I

INDENTED EDGE Trimmed and sculpted edge of a pot to give an indented 3D decorative effect. Created by hand or machine by cutting away the unwanted clay. Sometimes referred to a scalloped edge. Some experts refer to indented edge when the shaping is sharp and fine and refer to the scalloped edge when the shaping is more smooth and rounded. It is a subtle difference. See pic.

Many thanks to Ian Davenport for suggesting this definition

|

| Indented vs Scalloped Photos: Courtesy Ian Davenport Collection Date: May 2020 |

|

| Tea cup scalloping (or indenting) machine at Spode factory Stoke |

IMAGE TOYS Name sometimes given to Staffordshire pottery figurines.

IMARI PATTERNS Decoration. Heavy types of decorations (based upon brocade patterns) made for export at Arita, Japan, of which Imari is the seaport.

IMPRESSED This could be a potter, suitably impressed, exclaiming in Potteries dialect "Ast sane that, duck?" But more likely it is a mark on the pot created by a small tool which has been pushed (impressed) into the soft clay body as a means of identifying who made it.

|

| Impressed date mark on the underside of a pot |

INCISED Decoration. A method of ornamenting a clay pot by cutting the soft clay of its walls with a sharp instrument such as a pointed stick, knife blade, or piece of flint.

|

| Incised decoration German salt glazed pot - dated 1995 |

INGLAZE Type of decoration. The decoration is applied to the unfired glaze so that during firing, as the glaze matures, the decoration matures with the glaze and in it. The decoration may be hand painted, sprayed or silk screen.

INNA or INNER MICK Dialect. In a bad mood, probably as a result of some annoyance, and a tad rebellious.

INSULATORS Electrical Porcelain. Used in the generation, transmission, distribution of electrical energy, and ceramic components are used in most items of domestic and industrial electrical equipment. Electrical porcelain is made from the basic ceramic materials, china clay, ball clay, felspar and silica and sometimes other materials, the actual composition being varied to produce the requisite properties for the large variety of insulators required. The manufacturing processes are generally similar to those in the rest of the ceramic industry, but adapted according to the size of the insulators to be made.

|

| Insulators made by Bullers of Stoke-on-Trent In the clay state ready for firing Photo: source unknown Date: 1960s |

INTAGLIO Decoration. Sunken or incised ornaments.depressed below the surface so that an impression from the design yields an image in relief.

INTERMEDIATE HOLES Part of a bottle oven. On the crown of the oven. Similar to shoulder holes but positioned mid-way between the shoulder and the top of the crown.

INTERMITTENT OVEN Equipment. Any potter's oven which is successively placed, fired and drawn after cooling. Bottle ovens are intermittent.

IRON SCRODLEY A fault created in plastic clay when it is being pugged. "The end of the pug shaft should revolve in oil, this can be done by suspending a shaped tin to contain the same underneath the shaft. Revolving in oil keeps the pug cook, and prevents iron scrodley" From: PRACTICAL TREATISE ON THE MANUFACTURE OF POTTERY by John Gater, Consultant Potter, 1921

IRONSTONE Type of pottery with a particular recipe and requiring particular firing conditions. A hard, non-porous earthenware, usually of exceptional strength. The body of ironstone ware is particularly dense, for the reason, probably, that it contains a greater amount of Cornish stone than the majority of ordinary earthenwares. Doesn't necessarily contain iron or ironstone. The word 'ironstone' was introduced and popularised in 1813 by the Mason family, of Stoke-on-Trent who registered the patent. Other factories in The Potteries were already producing this type of ware but it was Miles Mason's youngest son Charles James Mason who at 21 years of age took out Patent No 3724, 31st July 1813 - a process for the "Improvement of the Manufacture of English Porcelain', IRONSTONE PATENT CHINA." The patent was granted for fourteen years but was not renewed, probably because the other major potters had perfected their own ironstone body recipes. So, though he did not invent the material, Charles Mason invented a name which perfectly described the product

IRON SPOT Pottery fault. Ugly, dark brown spot showing on the piece after firing. Caused by ferric material in the original clay. Removed by magnetting the clay slip in the slip house before it is used.

IRONY Potter's definition : When one big pottery factory closes in 2011 because "it is too expensive to manufacture in the UK but cheaper to import from lo-cost countries" but the factory is then purchased by a Chinese manufacturer and re-opened in 2012 to make pots in the UK "because it makes sense to manufacture locally since it saves transport costs, saves energy, saves the planet, is more flexible and is less expensive." That's pottery irony.

IVORY BODY Type of pottery with a particular recipe. Cream-coloured ware which retains the ivory tint that is imparted to it by the ball clay. (Many earthenware bodies are artificially whitened by the addition of a cobalt blue stain.)

back to top>

JACKED The firemouth doors or dampers on a bottle oven which are slightly open. Also known as cracked.

JACK SHARP Dialect. Stickleback fish in the local pond. Great for kids' introduction to fishing.

JAR MILL Equipment. Machine. In the sliphouse or laboratory. Small ball mill. Revolving cylinder made from tough material (sometimes thickly cast vitreous pottery). Containing grinding media (usually small ceramic balls) and used to grind small batches of trial body, ceramic colours or vitreous enamels.

JAW CRUSHER Machine. Slip house. For crushing hard rocks. Two jaws come together in a reciprocating motion so that the rocks are crushed between them.

JASPER WARE Type of pottery with a particular recipe and requiring particular firing conditions. Unglazed and fine, hard, vitreous stoneware stained with the addition of metallic oxides to create a variety of coloured bodies, with white or coloured embossed ornamentation sprigged onto the surface. Josiah Wedgwood became famous for it when he introduced it in 1774 but other potters also manufactured this type of ware.

JASPER DIP Type of decoration. Josiah Wedgwood and others including Adams and Dudson used this manufacturing method. Solid jaspers were turned from a solid piece of coloured clay but jasper dips were made by dipping the typically white solid jasper clay body in coloured clay slip to give the surface an entirely different and coloured appearance.

JED Dialect. Dead. Lifeless. Capput. "Eats jed!" meaning its lifeless. Also STOON JED meaning completely and utterly lifeless.

JERRY Chamber pot. Guzzunder

JET WARE Type of pottery with a particular recipe and requiring particular firing conditions. Red clay body with black manganese-type glaze. A twin term to Rockingham. Jet wares were at one time extensively made in the Staffordshire Potteries and were often elaborately decorated. Jet teapots were popular in strictly plain shapes with little or no decoration. Jet is recognised as a very suitable body to employ for teapot manufacture, possessing a variety of suitable qualities.

JET-ENAMELLED WARE Decoration. A porcelain that was decorated on-glaze with black engraved transfers at Worcester in the eighteenth century was called jet-enamelled ware.

JEWELLING Decoration. Jewelling was a hand decorating technique which involved raising the colour to give a soft coloured, textured, jewel-like finish. Usually carried out by gilders. As well as jewelling in colours, pearling produced rows of tiny pearls. Raised gold was often used in conjunction with the jewelling technique producing remarkable pieces which were exquisitely detailed and finely patterned. Always very expensive to produce, jewelled porcelain was reserved for the most luxurious dessert and cabinet wares. Spode first produced complicated designs in jewelled porcelain for the 1851 Great Exhibition. Although not particularly well received at the exhibition, the style became more and more fashionable towards the end of the 19th century strongly influenced by Middle Eastern art.

JIB Dialect. Face, more particularly, the chin.

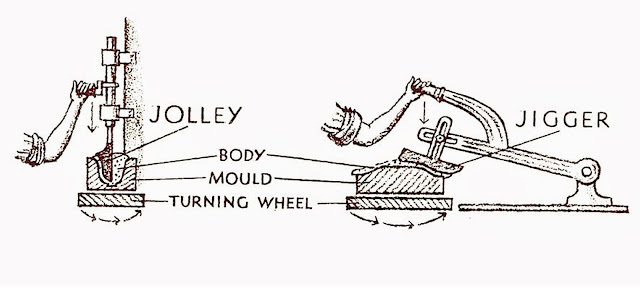

JIGGER Process. Making flatware on a jigger machine. Plates, saucers etc. The mould forms the inside or face of the pot. The metal profile on the jigger machine forms the back of the pot.

JIGGER Equipment. Potting department. Used by the jiggerer to jigger flatware - plates and saucers for instance.

JIGGERER Occupation. Potting department. Person who uses a jigger to create flatware. Sometimes jiggered up at the end of a long week of jiggering with a jigger.

JIGGERED UP Dialect. Need to go to bed due to lack of sleep, too much work or too much drink. Saturdays are usually days to be totally jiggered.

JIGGERING Process. Clay end. Making flatware. In jiggering, a shaped tool is slowly brought down onto the plastic clay body that has been placed on top of the rotating plaster mould. The jigger tool shapes one face, the mould the other. The term is specific to the shaping of flatware, such as plates, whilst a similar technique, jolleying, refers to the production of hollowware, such as cups and mugs and small bowls. Note that if someone is playing around and not concentrating they would be scolded and told to "Stop jiggering about!"

IRONSTONE Type of pottery with a particular recipe and requiring particular firing conditions. A hard, non-porous earthenware, usually of exceptional strength. The body of ironstone ware is particularly dense, for the reason, probably, that it contains a greater amount of Cornish stone than the majority of ordinary earthenwares. Doesn't necessarily contain iron or ironstone. The word 'ironstone' was introduced and popularised in 1813 by the Mason family, of Stoke-on-Trent who registered the patent. Other factories in The Potteries were already producing this type of ware but it was Miles Mason's youngest son Charles James Mason who at 21 years of age took out Patent No 3724, 31st July 1813 - a process for the "Improvement of the Manufacture of English Porcelain', IRONSTONE PATENT CHINA." The patent was granted for fourteen years but was not renewed, probably because the other major potters had perfected their own ironstone body recipes. So, though he did not invent the material, Charles Mason invented a name which perfectly described the product

IRON SPOT Pottery fault. Ugly, dark brown spot showing on the piece after firing. Caused by ferric material in the original clay. Removed by magnetting the clay slip in the slip house before it is used.

IRONY Potter's definition : When one big pottery factory closes in 2011 because "it is too expensive to manufacture in the UK but cheaper to import from lo-cost countries" but the factory is then purchased by a Chinese manufacturer and re-opened in 2012 to make pots in the UK "because it makes sense to manufacture locally since it saves transport costs, saves energy, saves the planet, is more flexible and is less expensive." That's pottery irony.

IVORY BODY Type of pottery with a particular recipe. Cream-coloured ware which retains the ivory tint that is imparted to it by the ball clay. (Many earthenware bodies are artificially whitened by the addition of a cobalt blue stain.)

back to top>

J

JACKED The firemouth doors or dampers on a bottle oven which are slightly open. Also known as cracked.

JACK SHARP Dialect. Stickleback fish in the local pond. Great for kids' introduction to fishing.

JAR MILL Equipment. Machine. In the sliphouse or laboratory. Small ball mill. Revolving cylinder made from tough material (sometimes thickly cast vitreous pottery). Containing grinding media (usually small ceramic balls) and used to grind small batches of trial body, ceramic colours or vitreous enamels.

JAW CRUSHER Machine. Slip house. For crushing hard rocks. Two jaws come together in a reciprocating motion so that the rocks are crushed between them.

|

| Jaw crusher jaws |

JASPER WARE Type of pottery with a particular recipe and requiring particular firing conditions. Unglazed and fine, hard, vitreous stoneware stained with the addition of metallic oxides to create a variety of coloured bodies, with white or coloured embossed ornamentation sprigged onto the surface. Josiah Wedgwood became famous for it when he introduced it in 1774 but other potters also manufactured this type of ware.

|

| Wedgwood blue jasper 1960 |

JASPER DIP Type of decoration. Josiah Wedgwood and others including Adams and Dudson used this manufacturing method. Solid jaspers were turned from a solid piece of coloured clay but jasper dips were made by dipping the typically white solid jasper clay body in coloured clay slip to give the surface an entirely different and coloured appearance.

JED Dialect. Dead. Lifeless. Capput. "Eats jed!" meaning its lifeless. Also STOON JED meaning completely and utterly lifeless.

JERRY Chamber pot. Guzzunder

|

| Jerry. Chamber Pot. Guzzunder |

JET WARE Type of pottery with a particular recipe and requiring particular firing conditions. Red clay body with black manganese-type glaze. A twin term to Rockingham. Jet wares were at one time extensively made in the Staffordshire Potteries and were often elaborately decorated. Jet teapots were popular in strictly plain shapes with little or no decoration. Jet is recognised as a very suitable body to employ for teapot manufacture, possessing a variety of suitable qualities.

JET-ENAMELLED WARE Decoration. A porcelain that was decorated on-glaze with black engraved transfers at Worcester in the eighteenth century was called jet-enamelled ware.

JEWELLING Decoration. Jewelling was a hand decorating technique which involved raising the colour to give a soft coloured, textured, jewel-like finish. Usually carried out by gilders. As well as jewelling in colours, pearling produced rows of tiny pearls. Raised gold was often used in conjunction with the jewelling technique producing remarkable pieces which were exquisitely detailed and finely patterned. Always very expensive to produce, jewelled porcelain was reserved for the most luxurious dessert and cabinet wares. Spode first produced complicated designs in jewelled porcelain for the 1851 Great Exhibition. Although not particularly well received at the exhibition, the style became more and more fashionable towards the end of the 19th century strongly influenced by Middle Eastern art.

JIB Dialect. Face, more particularly, the chin.

JIGGER Process. Making flatware on a jigger machine. Plates, saucers etc. The mould forms the inside or face of the pot. The metal profile on the jigger machine forms the back of the pot.

JIGGERER Occupation. Potting department. Person who uses a jigger to create flatware. Sometimes jiggered up at the end of a long week of jiggering with a jigger.

JIGGERED UP Dialect. Need to go to bed due to lack of sleep, too much work or too much drink. Saturdays are usually days to be totally jiggered.

JIGGERING Process. Clay end. Making flatware. In jiggering, a shaped tool is slowly brought down onto the plastic clay body that has been placed on top of the rotating plaster mould. The jigger tool shapes one face, the mould the other. The term is specific to the shaping of flatware, such as plates, whilst a similar technique, jolleying, refers to the production of hollowware, such as cups and mugs and small bowls. Note that if someone is playing around and not concentrating they would be scolded and told to "Stop jiggering about!"

|

| Making flatware on a potbank Jiggering cereal bowls Photo: unknown source Date: 1970s? |

JINNET A particular shape of saggar. Rectangular box with holes in its sides through which refractory ceramic pins were inserted. Two lines of triangular refractory saddles were placed in the base of the saggar. Plates were then placed in the saggar and made to rest upright on the saddles, each plate being separated from its neighbour by resting on the protruding pins.

JINNY SPINNER Dialect but not common. And not an occupation but an insect - a daddy long legs.

JOBS ON A POTBANK

There are many. Here's just a few:

Owner, Directors, Managers, Foremen, Supervisors, Office staff, Commercial travellers.

MAINTENANCE DEPT

Plumber

Painter

Electrician

Boilerman

Blacksmith

Carpenter

Owner, Directors, Managers, Foremen, Supervisors, Office staff, Commercial travellers.

MAINTENANCE DEPT

Plumber

Painter

Electrician

Boilerman

Blacksmith

Carpenter

Multi skilled man

Lodgeman / Lodge Keeper

Lodgeman / Lodge Keeper

Fitter

Die fitter

CLAY END:

Slip houseman

Slip maker

Mill man

Pug man

Slip houseman

Slip maker

Mill man

Pug man

Saggar maker

Saggar maker's bottom knocker

Clay carrier

Saggar maker's bottom knocker

Clay carrier

POTTING DEPT:

Designer

Modeller

Blocker

Case maker

Block and case maker

Mould maker

Mould runner

Jiggerer

Mould maker

Mould runner

Jiggerer

Jolleyer

Jolley sponger

Dish maker

Tower

Thrower

Turner

Presser

Baller

Dish maker

Tower

Thrower

Turner

Presser

Baller

Fettler

Figurine caster

Figure fettler

Holloware fettler

Fettler sponger

Sponger

Sponger

Cups foot wiper

Caster

Bench caster

Handler

Bench caster

Handler

Handle sponger

Clay department labourer

Attendant

Fireclay maker

Cup maker

Cup handler

Board carrier

Coffee pot and cream fettler

Clay department labourer

Attendant

Fireclay maker

Cup maker

Cup handler

Board carrier

Coffee pot and cream fettler

Overlooker

Casting Manager

OVENS DEPT:

Casting Manager

OVENS DEPT:

Biscuit placer

Fireman

Biscuit brusher

Sand blaster

Biscuit selector

Glazer

Glaze dipper

Dipper

Dippers attendant

Thimble Picker

Cranker

Crank placer (tiles)

Pinner

Cod placer

Glost placer

Bedder

Placer

Ovenman

Drawer

Kilnman

Oddman

DECORATING END:

Sand blaster

Biscuit selector

Glazer

Glaze dipper

Dipper

Dippers attendant

Thimble Picker

Cranker

Crank placer (tiles)

Pinner

Cod placer

Glost placer

Bedder

Placer

Ovenman

Drawer

Kilnman

Ware cleaner

Dippers assistant

Foot wiper

Dippers assistant

Foot wiper

Swiller

Ware Cleaner

Foot wiper

Backstamper

Ware Cleaner

Foot wiper

Backstamper

DECORATING END:

Engraver

Printer

Transferer

Printer

Transferer

Print mender

Lithographer

Groundlayer

Washer off

Lithographer

Groundlayer

Washer off

Decorators labourer

Hardening on placer

Hardening on placer

Bander

Bander and liner

Washbander

Liner

Freehand paintress

Artist

Guilder / Gilder

Artist

Guilder / Gilder

Burnisher

Decorating manager

Silk screen printer

Decorating manager

Silk screen printer

Stippler

Cutter

Paper cutter

GLOST / FINISHED WAREHOUSE:

Polisher

Warehouseman

Order picker

Packer

Carter

Stableman

Crate maker

Woman for laying out orders

One legged dancer?

Glost selector

Driller

Order picker

Packer

Carter

Stableman

Crate maker

Woman for laying out orders

One legged dancer?

For a huge and comprehensive list try here> http://www.thepotteries.org/jobs/index.htm

back to top>

JOGGLE Part of a multi-part mould. A location key which ensures all parts fit together correctly. Joggles are the equivalent to the natch. Modern joggles are made of durable plastic or metal and precision made to ensure accurate mould alignment, thereby eliminating imperfect, twisted seams.

JOGGLE NATCH Same as joggle or natch. The location key which ensures all parts fit together correctly.

JOLLEY Sometimes JOLLY. Process. Clay end. Making holloware - cups, mugs, small bowls in plaster of Paris moulds. The mould forms the outside of the piece. The jolley arm, called a monkey arm, and attached profile tool, creates the inside. Name also for the entire machine used to do the job. (Interestingly, and to confuse matters, in the 1840s jolley was the word used for making flatware.)

JOLLEY (JOLLY) Equipment. Potting department. Clay end. The entire machine used by the jolleyer (the potter) to jolley small sized holloware such as cups, mugs or bowls.

JOLLEYER or JOLLIER Occupation. Clay end. The potter who uses a jolley to jolley. Mostly jolly, but sometimes miserable with a "face lark a bosted clock". He or she creates holloware (eg: cup bodies) in a rotating plaster of Paris mould by using a jolley (with its profile tool and monkey arm) to create the inside shape of the pot.

JOLLEYING Process. Clay end. Potting shop. Using a jolley (equipment) to jolley (process) and thus to create holloware. First, the wedged or pugged clay which is quite soft and plastic is batted out on a spreader. The clay is then pushed into the Plaster of Paris mould. The mould forms the outside shape of the pot. Then, on a jolley, the potter brings down a profile tool made of steel into the inside of the fast rotating mould. The profile tool spreads the clay thinly into the mould and excess clay squeezes out. The unwanted clay is cut off. The mould is then allowed to dry during which time the clay inside the pot shrinks away from the mould. The potter can then remove the dry clay piece.

|

| Making flatware on a potbank Jolleying small holloware - cups or mugs Photo: source unknown Date: 1960s |

JOMUK Sanitaryware. A particular size of Belfast sink made out of fireclay. The jomuk measures 24 x 18 x 10 inches. With an overflow. More about sinks and their wonderful names here>

|

| Jomuk (Belfast sink) 24x18x10 inches |

JO JO TELL Dialect. B&B in Burslem.

JUMBO CUP or MAGNUM CUP Very large bowl-like cup with handle.

JUST NOW Dialect. Later. "Just be patient will you?!"

JYED Dialect. Coffin required. Sad. He was a nice sort of chap, he'll be missed.

back to top>

KALE or KAIL Work done by the youngest apprentice; sweeping the floor, lighting the fire (From the 2nd edition of Dialect Words & Phrases used in the Staffordshire Potteries. Thanks go to Paul Niblett for highlighting this quote and to Phil Rowley for putting us on to it. June 2021)

|

| JoJoTell |

JUMBO CUP or MAGNUM CUP Very large bowl-like cup with handle.

JUST NOW Dialect. Later. "Just be patient will you?!"

JYED Dialect. Coffin required. Sad. He was a nice sort of chap, he'll be missed.

back to top>

K

KALE or KAIL Work done by the youngest apprentice; sweeping the floor, lighting the fire (From the 2nd edition of Dialect Words & Phrases used in the Staffordshire Potteries. Thanks go to Paul Niblett for highlighting this quote and to Phil Rowley for putting us on to it. June 2021)

KALE GIRL An apprentice before taking on piecework.

KALED or KAILED Franked or buzzed or jiggered - late for work.

KALED or KAILED Franked or buzzed or jiggered - late for work.

KAOLIN Component of pottery body recipe. China clay. A fine clay used in ceramics and refractories. Also used as a filler or coating for paper and textiles. Kaolin production in the UK is confined to the primary deposits within the granites of South West England, Hensbarrow (St Austell) in Cornwall and Dartmoor (Lee Moor) in Devon. Kaolin is Britain's most important mineral export after hydrocarbons. Around 80% is exported, making a considerable positive contribution to the balance of payments. There are no significant imports. Kaolin production requires a large amount of waste to be removed. This consists of un-kaolinised granite, sand and mica. Each tonne of kaolin recovered typically produces up to 9 tonnes of waste.

KAOLINITE Component of pottery body recipe. A clay mineral, part of the group of industrial minerals, with the chemical composition Al2Si2O5(OH)4. It is a layered silicate mineral, with one tetrahedral sheet linked through oxygen atoms to one octahedral sheet of alumina octahedra. Rocks that are rich in kaolinite are known as kaolin or china clay. Kaolinite is mined, as kaolin, in Vietnam, Brazil, Bulgaria, France, United Kingdom, Iran, Germany, India, Australia, Korea, the People's Republic of China, the Czech Republic and the United States.

KAY-SEA Dialect word. Best leather football.

KECKS Dialect. Trousers - 'Trisers'.

KEDGE Dialect. Beg. "Can I kedge a lift in your car." Or to purloin.

KEEM Dialect. "Ner nerny ner ner!" That's kids for you.

KEGGY or KAGGY HANDED Dialect. Left handed. See Cack handed .

KERATIN Material used in the process. A protein. Used as an additive to plaster to slow down the rate of it maturing or 'going off.' A retarder.

KETCH Catch.

KICK WHEEL Part of a type of potters wheel.

KIDNEY Equipment. Similar to a potters horn. Sometimes made in metal, sometimes red rubber.

KILL Dialect. KILN. Oven. Bottle Oven. Enamel Kiln. Tunnel Kiln. Top Hat Kiln. Intermittent Kiln. Rapid Fire Kiln.

It's where the metamorphosis of clay, during firing, takes place. It's where the irreversible change from clay to pot upon which the whole of the craft and industry is founded. A change in the pottery body takes place in the kill at around 600°C. It's where clay loses its chemically-bound water molecules and can no longer be broken down by water. Once this change has occurred it cannot be reversed. This ceramic change converts fragile and crumbly dry clay from Mother Earth into hard, brittle ceramic. This is both a chemical and physical change to the structure of the clay. Magic by fire!

KILL BITS (KILN BITS) Pottery glaze fault showing as a very 'gritty' surface on the fired glaze. The size of the 'grittiness' varies. Caused by dirt and dust blowing around in the atmosphere of the glost kiln during firing. The dirt lands on the soft glaze surface, sticks to it and after cooling shows as a rough-to-touch gritty surface. If the contamination area is large the pot's glazed surface cannot be repaired and the piece is regarded as seconds or lump.

KILL FILL The amount of pottery ware loaded into the kiln or bottle oven for firing. Manufacturers want the maximum kill fill in order to maximise profit.

KILN Equipment. An entire building (as in the case of a bottle oven) or an installation designed and used for the firing of ceramic products at high temperature. Also, as a different design, for calcining, hardening on or sintering. May be intermittent, annular, tunnel, rotary, shuttle, skate, fast fire, top hat or shaft. There will be others, too. Strictly speaking this is not the same as an OVEN. See BOTTLE OVEN and BOTTLE KILN. Also see 'Don't Get Confused' tab

KILN CAR Equipment. A carriage ( looking like a small railway carriage with no roof or sides) used to support refractory kiln furniture which in turn holds pottery ware which is fired in a tunnel kiln. A train of kiln cars are pushed from one end of the tunnel kiln to the other. The metal undercarriage of the kiln car is protected by continuous sand seals along the length of the tunnel kiln. The car deck is entirely built of refractory material.

KILN FURNITURE Equipment. Refractory supports on which pottery is placed and stacked prior to, and during, firing: Bowl sling, Cup ring, Crank, Dot, Dump, Pillar, Pin, Pip, Post, Prop, Ring, Saddle, Saggar, Saucer ling, Setter, Spur, Stilt, Thimble, Tile clip ... and more.

KAOLINITE Component of pottery body recipe. A clay mineral, part of the group of industrial minerals, with the chemical composition Al2Si2O5(OH)4. It is a layered silicate mineral, with one tetrahedral sheet linked through oxygen atoms to one octahedral sheet of alumina octahedra. Rocks that are rich in kaolinite are known as kaolin or china clay. Kaolinite is mined, as kaolin, in Vietnam, Brazil, Bulgaria, France, United Kingdom, Iran, Germany, India, Australia, Korea, the People's Republic of China, the Czech Republic and the United States.

KAY-SEA Dialect word. Best leather football.

KECKS Dialect. Trousers - 'Trisers'.

KEDGE Dialect. Beg. "Can I kedge a lift in your car." Or to purloin.

KEEM Dialect. "Ner nerny ner ner!" That's kids for you.

KEGGY or KAGGY HANDED Dialect. Left handed. See Cack handed .

KERATIN Material used in the process. A protein. Used as an additive to plaster to slow down the rate of it maturing or 'going off.' A retarder.

KETCH Catch.

KICK WHEEL Part of a type of potters wheel.

KIDNEY Equipment. Similar to a potters horn. Sometimes made in metal, sometimes red rubber.

KILL Dialect. KILN. Oven. Bottle Oven. Enamel Kiln. Tunnel Kiln. Top Hat Kiln. Intermittent Kiln. Rapid Fire Kiln.

It's where the metamorphosis of clay, during firing, takes place. It's where the irreversible change from clay to pot upon which the whole of the craft and industry is founded. A change in the pottery body takes place in the kill at around 600°C. It's where clay loses its chemically-bound water molecules and can no longer be broken down by water. Once this change has occurred it cannot be reversed. This ceramic change converts fragile and crumbly dry clay from Mother Earth into hard, brittle ceramic. This is both a chemical and physical change to the structure of the clay. Magic by fire!

KILL BITS (KILN BITS) Pottery glaze fault showing as a very 'gritty' surface on the fired glaze. The size of the 'grittiness' varies. Caused by dirt and dust blowing around in the atmosphere of the glost kiln during firing. The dirt lands on the soft glaze surface, sticks to it and after cooling shows as a rough-to-touch gritty surface. If the contamination area is large the pot's glazed surface cannot be repaired and the piece is regarded as seconds or lump.

KILL FILL The amount of pottery ware loaded into the kiln or bottle oven for firing. Manufacturers want the maximum kill fill in order to maximise profit.

KILN Equipment. An entire building (as in the case of a bottle oven) or an installation designed and used for the firing of ceramic products at high temperature. Also, as a different design, for calcining, hardening on or sintering. May be intermittent, annular, tunnel, rotary, shuttle, skate, fast fire, top hat or shaft. There will be others, too. Strictly speaking this is not the same as an OVEN. See BOTTLE OVEN and BOTTLE KILN. Also see 'Don't Get Confused' tab

KILN CAR Equipment. A carriage ( looking like a small railway carriage with no roof or sides) used to support refractory kiln furniture which in turn holds pottery ware which is fired in a tunnel kiln. A train of kiln cars are pushed from one end of the tunnel kiln to the other. The metal undercarriage of the kiln car is protected by continuous sand seals along the length of the tunnel kiln. The car deck is entirely built of refractory material.

|

| Kiln car entering an electric tunnel oven. Wedgwood, Barlaston 1960 |

KILN FURNITURE Equipment. Refractory supports on which pottery is placed and stacked prior to, and during, firing: Bowl sling, Cup ring, Crank, Dot, Dump, Pillar, Pin, Pip, Post, Prop, Ring, Saddle, Saggar, Saucer ling, Setter, Spur, Stilt, Thimble, Tile clip ... and more.

back to top>

KIMKAM Dialect. Gossip. Usually derogatory.

KINNDED OFF Process. Oven dept. Past tense of kindle. Getting the fire going with wooden sticks and screwed-up newspaper to light the coal. Used by Alfred Clough when he fired the Last Bottle Oven organised by Gladstone Pottery Museum in 1978.

KINDLE Process. Ovens department. At the start of bottle oven firing. Getting the fire going. Layer of coal, layer of newspaper on top of that, layer of dry wood sticks on top of that, layer of coal on top of that. Then set the newspaper alight, not with a single match but with a flaming torch (similar to an Olympic torch) - a short pole with a burning oily rag fixed at one end.

KINDLING Material. Used during the firing process. Dry flammable material to get the coals lit. Newspapers loose and scrunched. Dry, wooden sticks.

KINDLING Starting a fire.

|

| Bottle ovens - kindling in one of the firemouths to start the firing Photo: source unknown, location unknown. Date: early 1960s |

KINDLING TIME Process. Starting the bottle oven firing. If it is done right it won't take long and the coal gets going and within an hour all mouths should be lit.

KIND SLICE Dialect. Council House.

KISSERS and GAPPERS Opposites. Faulty products, mainly flatware (plates). Words used to describe distorted plates as seen in a bung, usually in the biscuit state, probably before selection (inspection). Gappers is used when the distortion makes rims of plates separate from each other in the bung to create an obvious gap. Kissers is used when the distortion makes the rims of the plates touch. These words are possibly peculiar to the Steelite, and possibly the Royal Doulton pottery factories. Many thanks go to David Tabbernor for sending me these. October 2019

KITCHEN SINK See SINK. There is lots of info.

KNOCKED UP Pregnant. May be accidental, may be planned.

KNOCKER Equipment. May be specific to Wedgwood. Used in figuremaking. Specially-made wooden mallet-like tool. Used by figuremakers to bash jasper clay into the porous figure mould. (Figures being the applied raised clay ornaments decoration on Jasper ware.)

KNOCKING or KNOCKED Pottery glaze fault. Accidental removal of the dry glaze on a pot after dipping but before glost firing. The result is a dry patch, without glaze, after firing.

KNOCKING IN Process. Same as Knocking On. Also known as CENTRING

KNOCKING ON Process. Decorating department. Also known as CENTRING. Skilled process for men or women. The means by which a circular shaped pot (a plate, for instance) is tapped and nudged so that it lies perfectly centred on a small revolving round table.

KNOCKIN ON Elderley. Getting on a bit. Owd un.

KNOCKINGS Same as knottings. The oversize and waste material found on the top of a lawn (sieve) after slip has passed through it.

KNOCKING UP HAMMER Equipment. Decorating department. Tool. Used in engraving.

KNOCKY NONE or KNOCKY NIN Dialect. See above.

KNOCKY STAY THIN Dialect. Hefty punch in the face.

KNOP Knob for a lid.

KNOTTINGS The oversize and waste material found on the top of a lawn (sieve) after slip has passed through it. Essentially rubbish.

KNOTTINGS BOX Equipment. Used in the sliphouse. Where the knottings are disposed of prior to being thrown away completely.

KNUCKLING UP Process. Clay end. Part of the throwers art, craft, and skill. After coning up once or twice to remove air bubbles and to produce a consistent body to work with the thrower would begin to raise the pot on the wheel. He did this by trapping the rotating clay between the knuckles on his left hand (which forms the inside of the pot) and the knuckles on his right hand.

KNUCKLER Kiln Furniture. A scotch of a particular size and dimension made in fireclay or refractory brick and used as a wedge to support a bung of saggars.

back to top>